The Canton Nissan plant has hosted an annual Family Day for more than 15 years to celebrate its employees, their families, community partners, and members of the surrounding community. CAVS-E hosted a booth at this year's event to showcase its 3D Printing/3D Scanning, Room Scanning, and Simulation capabilities.

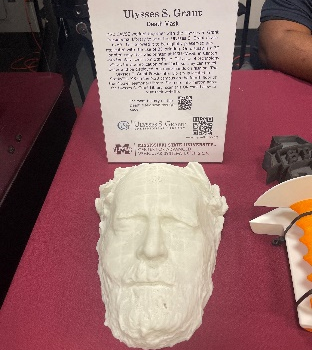

As a representation of its 3D Printing/3D Scanning capabilities, Jonathan Howell of CAVS-E showcased the Ulysses S. Grant Death mask. This was based on a project CAVS-E performed with the Ulysses S. Grant Presidential Library on the MSU campus, where Howell scanned a plaster version of the death mask artifact and the MSU Technology and Innovation group converted it to a 3D model. CAVS-E was then able to 3D print a replica of the historical artifact to display at the Nissan Family Day to illustrate the use of technology for digital historical preservation.

Jonathan Curtis displayed CAVS-E's Faro Focus Room Scanner to show how it can capture precise measurements of building features in a matter of minutes. To demonstrate these capabilities, Curtis showed fly-through videos of the training center that were previously created, as well as some scans taken of the STEM zone room where the booth was located.

Representing CAVS-E capabilities in simulation, Adam Collins and Travis Hill showcased videos of several FlexSim simulation models used to improve processes for Mississippi manufacturers, such as Nissan. Collins and Hill showed how CAVS-E could build manufacturing service system in a virtual environment using process layouts, data, and logic for companies to test their performance systems. These simulation models allow CAVS-E to validate and improve the manufacturer's system plans to address problems before they are made real. This proactive planning technology can offer substantial cost savings that help keep Mississippi's industry competitive.

For more information on these engineering solutions, or to learn about other programs and services offered by CAVS-E, or visit the CAVS-E website at cavse.msstate.edu.